Cable assembly

Welcome to Alpha Therm GmbH – your competent partner for high-quality components, individual solutions and professional cable assembly.

We offer you not only first-class products, but also customized assembly options to meet your technical requirements efficiently and precisely.

Customized cable assembly – individual, flexible, reliable

As an experienced and reliable provider, we know that: Every project is unique. That’s why we assemble the components we use and sell exactly according to your specifications – from individual cable lengths and connector types to special pin assignments or cable protection measures.

You specify – we implement. On request, we can also suggest suitable alternatives to hard-to-find or cost-intensive components.

Cable assembly is a key component of reliable connection technology – whether in sensor technology, medical technology, mechanical engineering or other industries. Thanks to our extensive selection of cables, connectors and accessory components, we can offer you tailor-made solutions for almost any application.

Our services at a glance

We offer you far more than just standard assembly:

- General cable assembly with various connectors

- Customized sensor solutions

- PCB solutions – from development to assembly

- Overmolding in low-pressure or high-pressure processes

- Rapid prototyping for short-term development projects

- Production of small, medium and large series

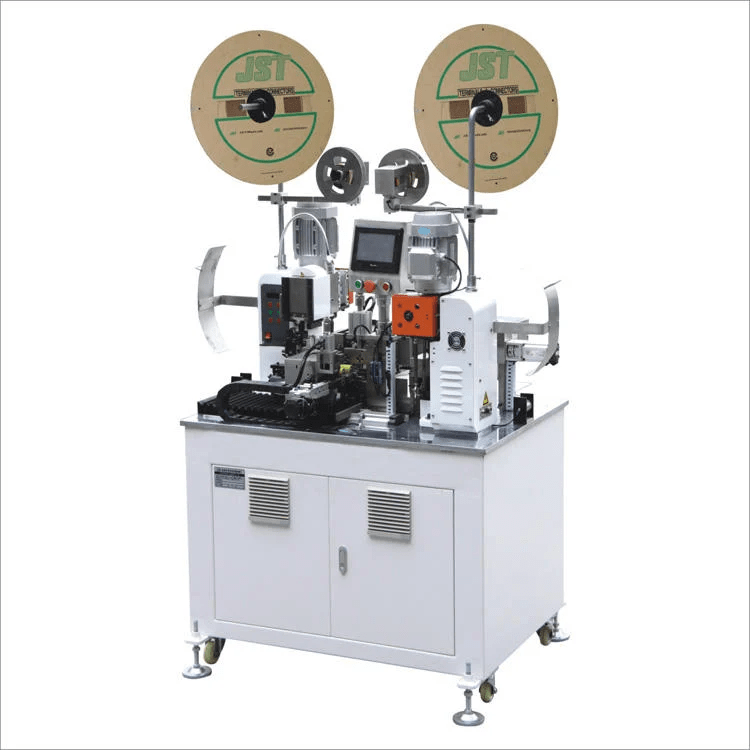

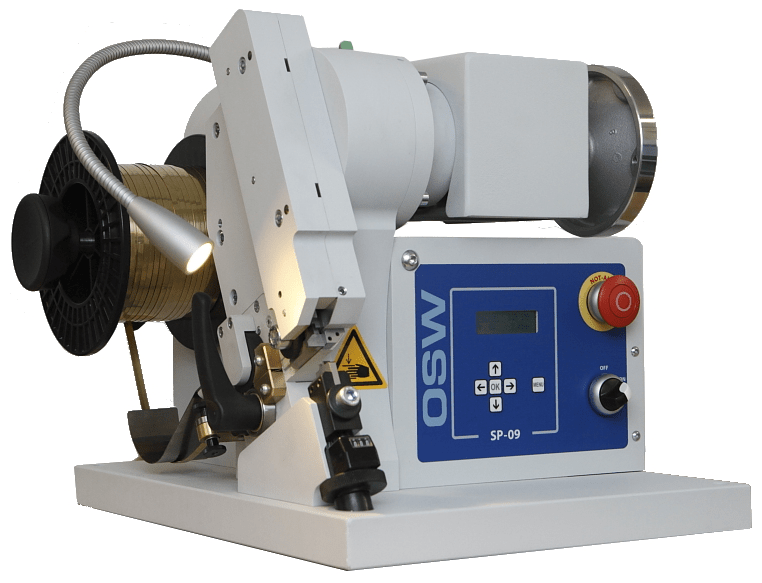

- Flexible automation solutions: For very high quantities, we realize semi- or fully automated production systems within a very short time in order to implement your projects efficiently and economically

High-quality brand components

We only use quality components from renowned manufacturers, including

- Molex

- JST

- TE Connectivity / AMP

- Harwin

- Aptiv

- Other established providers on request

Of course, we also use components provided or specified by the customer.

Quality is our benchmark

Quality comes first at Alpha Therm GmbH – at every stage of the process.

Because we know that: Reliability, dimensional accuracy and long-term stability are essential for our customers. That’s why we rely on a multi-stage quality concept:

- 100 % final electrical testing of all prefabricated assemblies

- In-process controls for continuous monitoring of dimensional accuracy and processing quality

- Visual and functional tests according to defined test instructions

- Careful incoming goods inspection of all purchased components

- Sorting out defective primary materials, which are transferred to a separate restricted storage area and analyzed

- Traceability of all components and production steps

- Documentation and archiving of test results if required

Our goal: Zero errors. Maximum customer satisfaction.

Our machinery – for efficiency & precision

We rely on modern technology to manufacture precisely and economically:

- Cut & strip machines for stranded wires and multi-core cables

- Splicing machines for high-strength joints

- Soldering stations (manual & semi-automatic)

- Crimping machines with interchangeable applicators for a wide range of contacts

- Shrink tunnel for mechanical protection

- Potting stations incl. oven curing for durable electronic potting solutions

- Hybrid press (electric / pneumatic / hydraulic) for large-sized contacts

- Special applicator for hexagonal pressings with variable geometry

Contact us today to find out more about our customization services. We look forward to successfully implementing your project – from the first prototype to series production.

Alpha Therm GmbH – your partner for customized cable assembly, flexible automation and uncompromising quality.